Functionality Built-In,

Not Bolted On

Functionality Built-In,

Not Bolted On

Within the various types of plastic centric manufacturers, you will find fabricators requiring rare functionality such as rotational mold planning and scheduling, concurrent processing, multi-cavity planning, and formulations within the Bill of Materials (BOM). Specialized routing capabilities also increase the need for industry-specific capabilities.

Addressing challenges like estimating, machine attributes, and by-products, (like, regrind material), further underscores the necessity for ERP systems specifically designed for plastics fabrication.

Unique Infor Syteline Capabilities

Unique Infor Syteline Capabilities

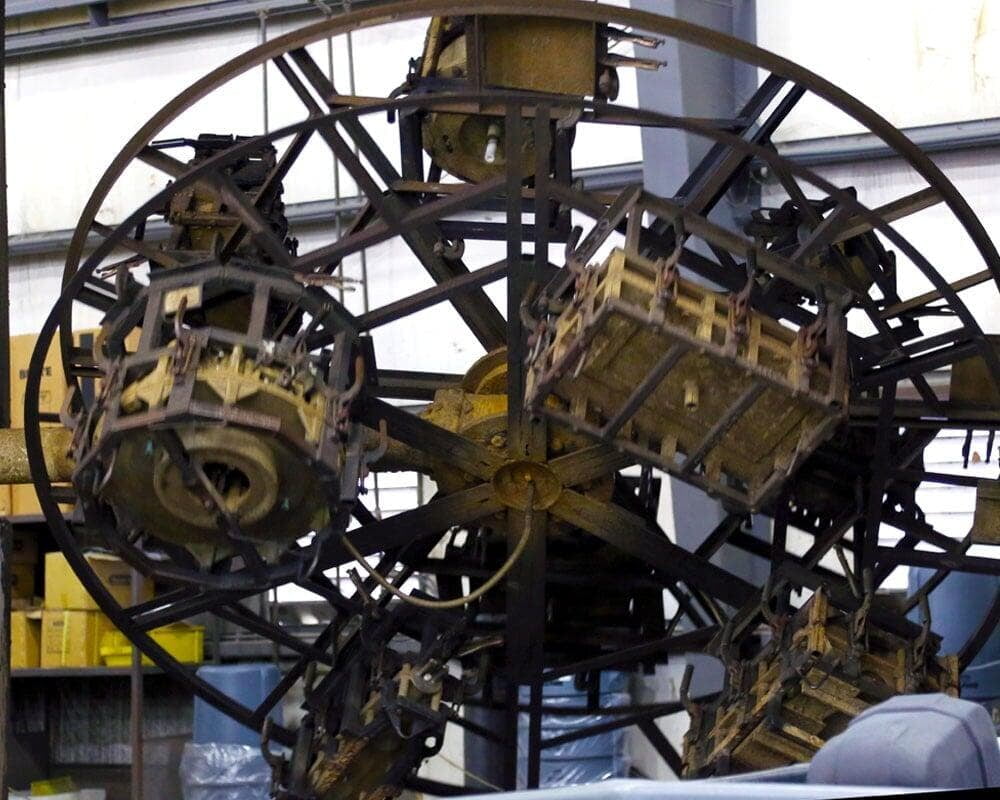

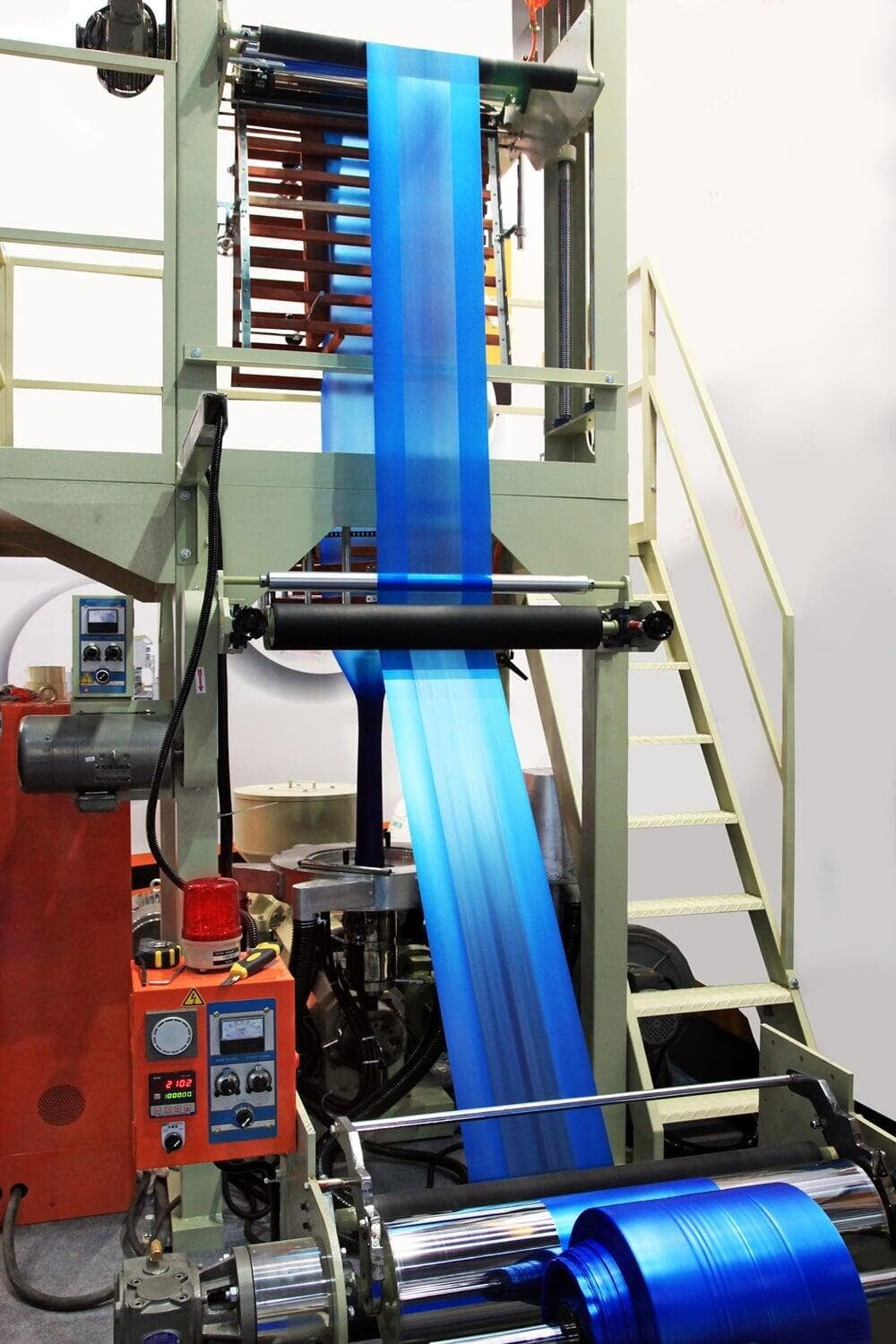

Rotational Molding is a manufacturing technique that starts by filling a heated mold with plastic material. Hollow components are formed by rotating the mold around two perpendicular axes. This causes the molten plastic to spread evenly and stick to the mold’s interior walls. A uniform thickness throughout is ensured by the continuous rotation during both the heating and cooling phases, preventing any unwelcome sagging or deformations. This technique can produce hollow plastic products with consistent wall thicknesses, intricate geometries, and exceptional strength.

Infor ERP Plastic Fabrication Customer Stories

"Infor ERP Business in the cloud gives us the scalability to support future growth without forcing us to increase our IT and administrative costs. Having data in the cloud enables us to focus on our core business and leave system and hardware administration and backup to Infor."

Adrian King

CFO

Gloucester Engineering

Other ESS and Infor ERP Customers

Other ESS and Infor ERP Customers

Would you like objective advice from an ERP advisor?

Do you have any questions about ERP selection, implementation, or any other issues regarding digital transformation? Chat with one of our advisors anytime. We'd be glad to help.

ESS’ promise to you: If the ERPs we work with are not a fit, we will point you to other systems that are.