Process Manufacturing ERP Software

Delivering Faster Responses That Drive Customer Loyalty and Lower Costs

Infor ERP is popular with process manufacturers

3,000+

Process Manufacturing Customers

4 of Top 6

Top Soap & Detergent Brands

5 of Top 7

Top Fertilizer Companies

4 of 5

Top Bakeries

4 of 5

Top Brewers

8 of 10

Top Dairies

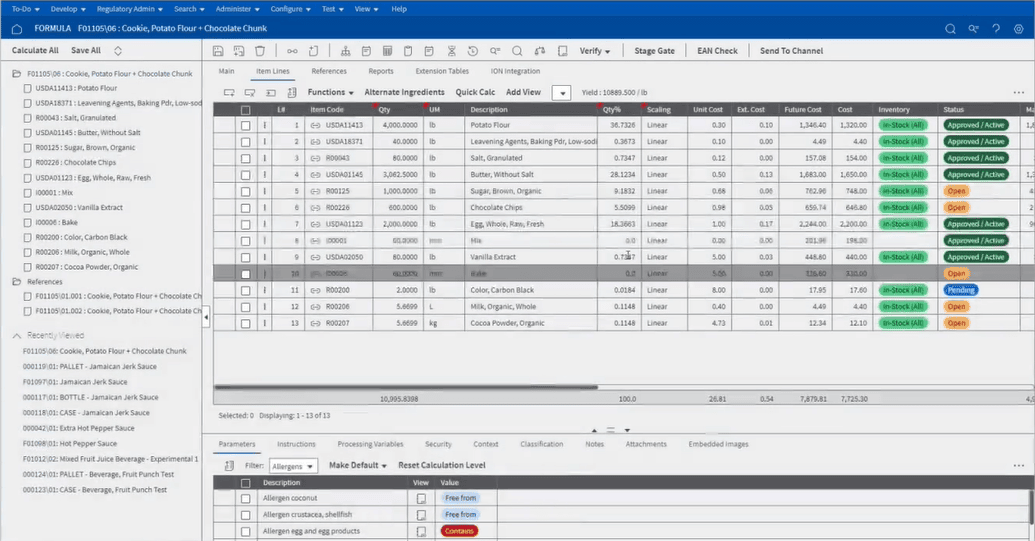

Minimize the time spent tweaking and assessing formulas, enabling teams to concentrate on innovation and developing products.

Formula Management

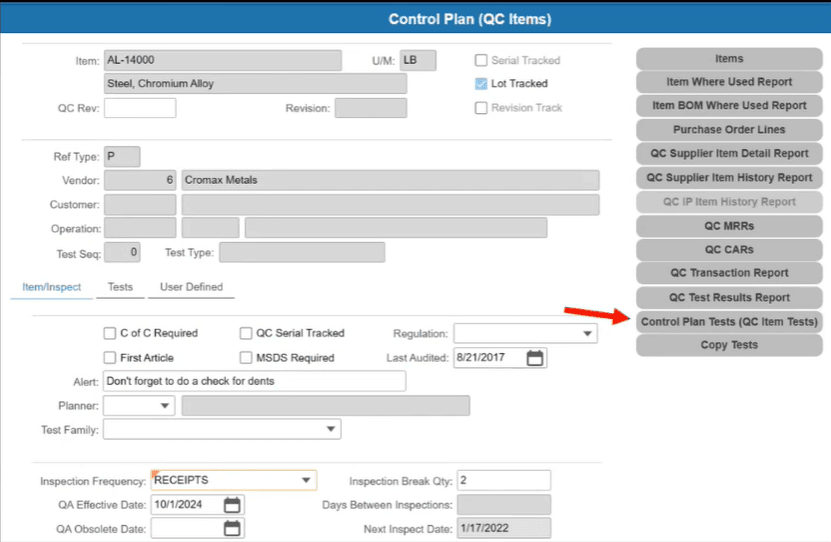

Cradle to Grave Traceability

It’s essential to have full visibility into where specific serial- and lot-tracked items are used and shipped, with complete traceability—including detailed tracking of serial-numbered components used within other serial-tracked products.

The ability to respond quickly helps attract customers and reduce costs.

Order Lead Times

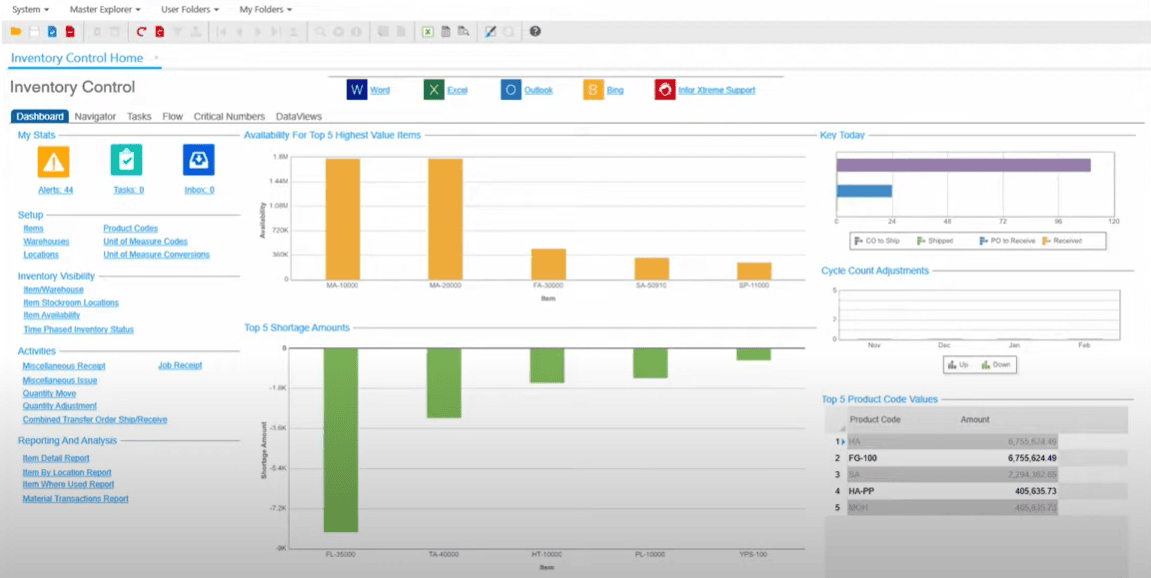

Process manufacturers often produce based on forecasts rather than actual demand. Creating a difficult balance—producing too little can lead to stockouts, while producing too much risks expired inventory (past its shelf life) and high carrying costs.

With Infor’s process manufacturing ERP, businesses can continuously plan production based on real-time data, optimized inventory levels, eliminating waste, and meet customer demands.

Infor ERP Process Capabilities Built-In, Never Bolted-On

Infor ERP Process Capabilities Built-In, Never Bolted-On

You will replace most disparate data silos with Infor’s integrated industry-specific capabilities and without disruption. Infor will also reduce risk via world-class security and uptime, all enabled by this modern ERP solution for process manufacturers.

Boosting Operations with Cloud-Based Efficiency

Tate’s Bake Shop, a Long Island cookie brand turned global success, used Infor CloudSuite Industrial to streamline operations. The cloud solution enabled smooth migration, better cost visibility for smarter financial decisions, and improved productivity through enhanced data integration.