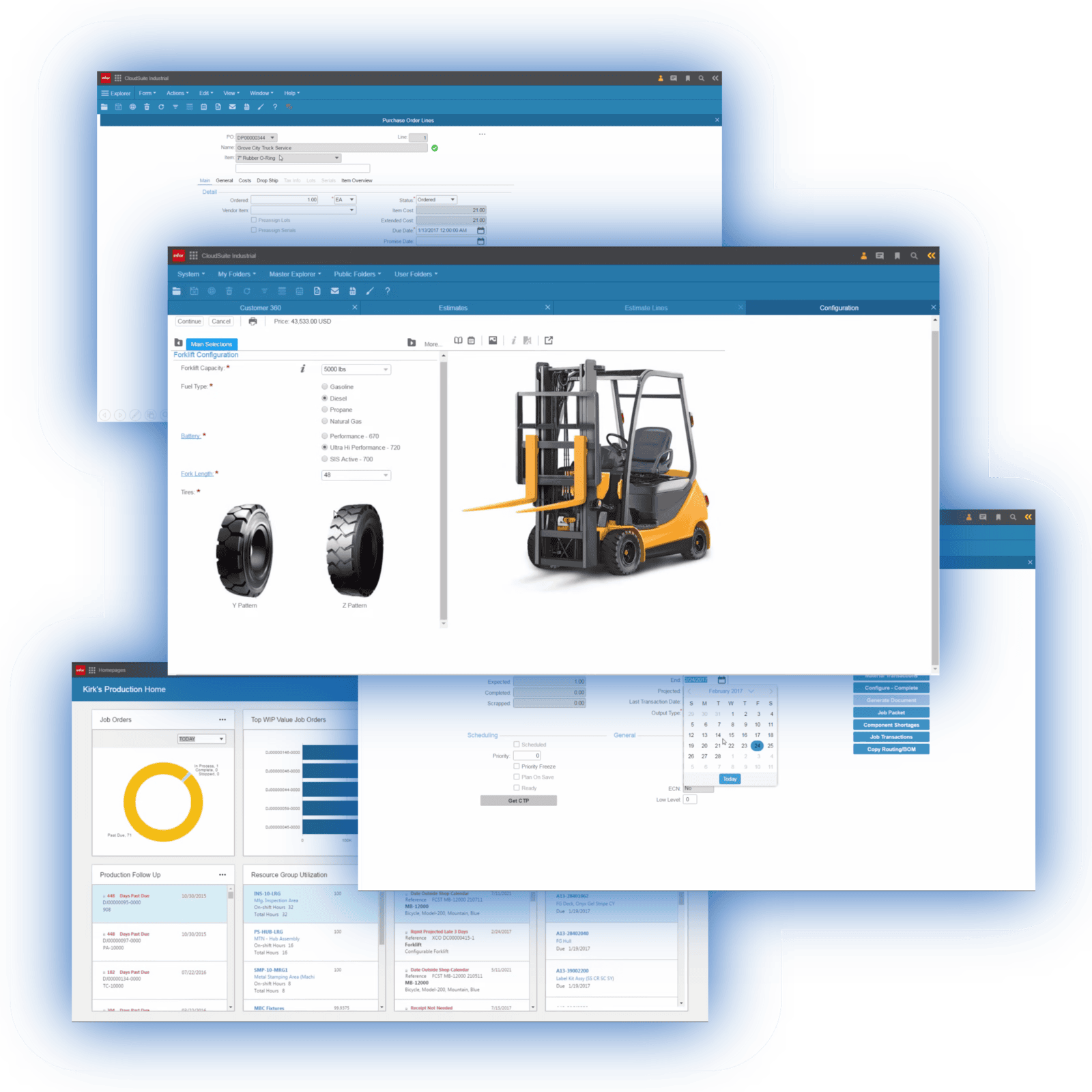

Infor CloudSuite Industrial

- Make-to-order (MTO),

- Configure-to- order (CTO),

- Engineer-to-order (ETO),

- Make-to-stock (MTS),

- Mixed-mode,

- and batch process environments that expect real-time visibility.

Cloud-native, multi-tenant on AWS

Delivered on the enterprise-grade AWS cloud, Infor CloudSuite Industrial combines deep manufacturing capabilities with a secure, scalable multi-tenant architecture. Continuous updates are applied automatically, creating a modern foundation ready for AI-driven innovation.

Modern, role-based user experience

Infor CloudSuite Industrial features a clean, intuitive interface designed around real work patterns. Role-based dashboards and configurable homepages highlight what matters most to each user. From planning teams to the shop floor, every role gets a focused, task-driven view.

AI-enabled unified platform

Running on the Infor Industry Cloud Platform, Infor SyteLine brings together security, automation, analytics, and extensibility in one environment. AI-powered insights, workflow automation, and compliance tools work seamlessly to keep operations efficient and aligned as you scale.

Embedded analytics and intelligence

Integrated dashboards, KPIs, and analytics provide immediate visibility into operations. Track supplier performance, inventory status, and service metrics in real time. With fewer data silos and improved accuracy, teams can make faster, more confident decisions.

Industry specific workflows built in

Preconfigured workflows and templates accelerate Infor SyteLine deployments by minimizing complexity and customization. From MRP and production planning to quality and finance, processes are based on proven manufacturing best practices for smoother, more predictable rollouts.

Designed for industry-specific

Purpose-built for complex manufacturing environments including engineer-to-order, configure-to-order, mixed-mode, and high-volume production, as well as service and project operations. Embedded industry logic ensures the system mirrors how your business actually runs.

What makes Infor CloudSuite

different than other ERPs?

- Deployed natively in the cloud, on-premises or hybrid, and supports multiple countries, languages, currencies, plants and warehouses.

- Built in role-based dashboards, analytics, shop-floor tracking, costing and scheduling. Not bolted on.

- No need for costly customizations which can delay implementation and tangle future upgrades.

- Unmatched scalability allows you to add branches or locations, without downtime and extensive IT overhead.

- Forecasting, procurement, inventory, shipping, role-based dashboards and KPIs, and more are built right into the core solution.

What is Infor

CloudSuite used for?

- Lead to Order

- Order to Cash

- Procure to Pay

- Plan to Inventory

- Design to Release

- Demand to Build

- Inspect to Correct

- Service to Cash

- Service Contract to Cash

- Project to Profit

- Financial Plan to Report

- Multi-Site Operations and Finance

A complete solution for finance departments that includes everything you expect including Fixed Assets and Human Resources. Infor CSI allows them to control costs while maintaining visibility and transparency between departments.

Costing

CSI records everything, e.g. material, labor, machine time, outside services, as it happens. That means your cost data is always up to date, not a month behind.

You choose how you want to measure costs: you can fix a target cost (standard costing), or track actual costs real time. And different parts or product lines can be costed uniquely. One might use FIFO, another average cost, another lot-specific, depending on what fits best.

You will see the true margin for every order and part, not just estimates. You clearly see the real costs to make things, so finance, engineering, and operations are all working from the same ‘song sheet’.

General Ledger

CSI records every transaction, and auto-creates accurate financial statements. It can manage one site or many plants under one or many financial entities. Utilizing a flexible chart of accounts that matches your business needs, analyze budgets, performance, and drill down to the original transactions.

Accounts Payable

Keep your finger on every invoice, due date, and payment. You see the full picture all in one place. You avoid missed payments or duplicate bills, manage cash flow better, and make smarter financial decisions.

Accounts Receivable

Track every invoice, payment, and credit in real time. Know who has paid, who hasn’t, and how much is still outstanding. Your team will see the full customer picture to improve cash flow, reduce bad debt, and strengthen customer relationships.

Human Resources

Manage everything about your people from job applicants to long-term employees. CSI keeps all employee information in one place, like contact details, positions, skills, and performance data, and can produce standard HR reports when needed. When connected to the Payroll module, it automatically shares data like hours and pay rates, so you don’t have to enter the same information twice while saving time and reducing errors.

CSI tracks every complex project from bid to delivery. Your Project Managers will easily track all the moving parts— materials, labor, milestones, costs, and revenue, tied directly to production and finance. You will know what each phase costs, compared to budgets, and even real time profitability while the project is in progress, not months later. Automatic alerts are sent when tasks or milestones complete, so no one waits for updates. And Projects are flexible — you can track customer projects, internal capital jobs, or even R&D — anywhere you need to manage time, money, and accountability.

Module Features:

- User defined Project Types and Cost Codes

- Multi-level % to complete analysis

- Revenue recognition by milestones

- Invoice milestone billing

- Invoice and Revenue milestones in all currencies

- Retention invoices

- Microsoft Project bi-directional integration

- Work Breakdown Structures

- Budget by period, compared to labor and expense reporting

- Proactively alerts Project Managers on any Projects, Project Tasks, and Project Resources outside of tolerance (Schedule or Cost Code Variance).

- Project Change Tracking

Your production plan will run like a precision machine. Instead of reacting to what’s late or running short, APS looks at your real capacity, materials, and customer demand simultaneously — creating the most efficient schedule possible.

Promise realistic delivery dates even while estimating or taking the order. CSI also plans material and capacity concurrently, so all resources (machines, people, inventory, etc.) are always in sync. Spotting available schedule time, automatically filling gaps, and keeps production flowing smoothly.

That means less overtime, less expediting, lower WIP and inventory, and far fewer surprises. Lead times shrink, throughput rises, and delivery performance improves — because you finally have a plan that actually works. In short, APS helps you work smarter, not just harder, from order to shipment.

Infor Production Control is the heart of every manufacturing operation — it ensures the right product gets built, the right way, at the right time. CSI gives full visibility into what’s happening on your shop floor: which machines are running efficiently, which materials are needed, which jobs are in progress, and what’s coming next.

Instead of guessing by juggling spreadsheets, you see a clear, real-time picture of capacity, inventory, quality, and scheduling.

Coordinating staff, equipment, and materials to ensure work flows smoothly through every routing stage. Fewer delays, fewer shortages, and fewer surprises.

Production Control helps you deliver exactly what the customer ordered — on time, at the right cost, and with consistent quality. CSI transforms complexity into control, and profit.

Infor’s Production Control module gives you the flexibility to plan and run jobs the way your factory works.

- Production Schedules: Schedule by plant, planner, product family, or even a key customer — whatever makes the most sense for your business. That keeps the big picture organized while still managing the details.

- Job Creation: Create jobs to fit your workflow —for one-off builds (high mix/short run), to low mix/long run orders, or from forecasts and schedules. It adapts to your production environment, whichever manufacturing environment you utilize.

- Scheduler: Groups different items into one batch to process together — perfect for minimizing setups. Effectively schedule machine time while minimizing changeovers.

Your company’s built-in insurance policy for product integrity. Woven into every part of your operation, from purchasing to shipping. QMS helps you meet and exceed customer specs, comply with regulations, and stop quality problems before they become expensive failures.

QMS is your digital quality department — one that never sleeps, never forgets, and never loses paperwork. Giving you tools to handle non-conformances, corrective actions, inspections, audits, and traceability — all automatically linked to your ERP data.

Enterprise-Wide Quality Control

QMS is pervasive throughout your operation — supplier quality, in-process checks, and customer returns. Manage manufacturing, maintenance, safety, training, even continuous improvement. Everything is tracked, reviewed, and verified in one consistent process.

Supplier Quality (QMS Supplier)

When materials arrive, the system automatically triggers receiving inspections. If out of tolerance, the lot is auto-isolated, alerts QC, and handles the vendor return with a built-in RMA process. It even tracks supplier performance, so you know who’s helping you — and who’s costing you.

In-Process Quality (QMS In-Process)

On the shop floor, QMS captures inspections, test results, defects, and rework details as they happen. Track parts, serial numbers, and jobs and trace any issue back to its source instantly. You’ll see the cost of scrap, labor, and material tied directly to each defect, giving you hard numbers for process improvement.

Customer Quality (QMS Customer)

CSI ensures all required inspections and documentation are complete. If a product is returned, it routes the item through QC, logs the issue, and links to a customer complaint record. You track the cause, corrective action, and follow-up — all documented and auditable.

Non-Conformance & Corrective Action Management

Any issue — whether from suppliers, production, or customers — is logged as a non-conformance. QMS documents the root cause, the corrective action, the cost, and when the corrective action is complete. It builds a full audit trail without a paper chase ever.

Cost of Quality Tracking

Every scrap, rework, and corrective action has a cost. QMS captures those costs, categorizes them, and ncovers where poor quality is impacting profit — so management can make real, data-backed decisions to improve.

Process Templates & Change Management

QMS ensures that everyone follows the same procedure every time. You will create standard process templates for inspections, audits, and reviews, while requiring completion before closing any issue. It keeps your process controlled and repeatable — exactly what auditors want to see.

Infor Factory Track is the data collection system that connects what’s planned to what’s actually happening on the shop floor — in real time. It eliminates paperwork, manual data entry, and delays that separate engineering, production, and inventory from each other. When something moves, gets built, or gets shipped, Factory Track ensures your ERP is aware instantly.

All built into Infor CSI, so it speaks the same language as your ERP — no clunky integration or duplicate entry. The Factory Track suite has three main parts, each handling a critical piece of your operation:

Shop Floor

Instead of clipboards and manual logs, operators use touch screens or barcode scanners to record what they’re working on — start and stop times, quantities, scrap, and materials used. It’s completely paperless and feeds that data straight into your ERP.

Time Track

Employees clock in and out, track breaks, and record labor directly in the same system they use for job reporting. It automatically organizes data for payroll and job costing, tracking and scheduling.

Warehouse Mobility

Workers use handheld barcode scanners to receive materials, move inventory, issue parts to jobs, or ship finished goods — all connected live to your ERP.

This is where your company’s strategy meets your factory reality. Connecting sales forecasts, production capacity, inventory, and financial goals into one unified plan — again everyone is working from the same ‘song sheet’.

Balance demand and supply intelligently. If sales anticipates a surge next quarter, S&OP shows how that affects material needs, labor capacity, and cash flow. If a key supplier runs late or demand drops, it lets you model “what if” scenarios instantly — so you can adjust your plan proactively.

How It Works:

- Demand–Supply Balancing: Plan by part number, product line, customer, or region —and proactively know if your plant can meet that demand without overproducing or running out of stock.

- “What If” Simulations: Test different sales forecasts or production plans and immediately see the financial and operational impact. It’s like a crystal ball for capacity and cash flow.

- Process & Collaboration: Everyone — from sales and marketing to finance and operations — works from the same system, with assigned tasks and due dates. The workflow ensures decisions are made on time and documented for accountability.

- Common Information Hub: It pulls real data from your ERP — demand, inventory, production, and sales — and consolidates it into one version of the truth for analysis and decision-making.

- Financial Alignment: The system syncs units and currency so finance sees the same picture as production — no more confusion between “what we plan to make” and “what we did make.”

- Alerts & KPIs: If forecasts shift or supply falls behind, everyone is alerted immediately. Built-in KPIs help you measure performance, track assumptions, and continuously improve your planning process.

Infor S&OP closes the gap between operations and strategy. It gives you visibility from the top floor to the shop floor — letting you plan based on facts, not gut feel. Better delivery performance, less excess inventory, fewer surprises in production, and a clearer picture of profitability.

Infor S&OP ensures your entire company is rowing in the same direction — at the right speed, with the right resources, and toward the same goal.

The bridge between supply and demand (your factory and your customers) — ensuring every quote, order, and promise you give is accurate, realistic, and profitable.

It ties your sales, customer service, production, and inventory together in real time. When a customer calls asking for a quote — the system instantly checks product configuration rules, pricing, material availability, and capacity on the shop floor. You can tell customers immediately what can be built, when it can ship, and how much it will cost.

- Real-Time Availability: The system checks materials, labor, and machine capacity automatically before committing to a delivery date — you promise what you can produce.

- Smart Quoting: Build complex quotes in minutes with accurate configurations and customer-specific pricing. No more manual lookups or quoting errors.

- Instant Order Conversion: Convert approved quotes into production orders at the push of a button — no re-entry, no lost details.

- Automated Validation: Built-in checks catch invalid configurations, pricing errors, or credit issues before the order moves forward.

- Integrated Communication: Every quote, change, and delivery update is recorded and visible across departments — so sales, engineering, and production are always aligned.

- Customer Follow-Up: Keep track of follow-up tasks and customer commitments, ensuring no call or issue slips through the cracks.

Infor Customer Service & Order Management transforms your quoting and order process into a seamless, reliable system — so customers get answers faster, and your factory delivers exactly what was promised, on time, every time.

The system that keeps your production running smoothly with complete, real-time control over your materials — where they are, what they cost, and when you’ll need them. It ties together purchasing, planning, and inventory so you always know what’s available, what’s on order, and what’s at risk of shortage.

You buy smarter, store smarter, and plan smarter — ensuring you’ve got the right materials in the right place at the right time, without overstocking or scrambling at the last minute.

- Multi-Site Inventory Control: Track inventory across multiple warehouses, plants, or even supplier locations, with instant visibility into quantities, costs, and locations.

- Smart Purchasing: Create and manage purchase requisitions, standard or blanket POs, and vendor quotes in one place. You can buy materials for stock, a specific job, or even a customer order directly — whatever fits your workflow.

- Complete Traceability: Every item can be tracked by lot or serial number — from purchase through use, shipment, or return — ensuring full traceability, compliance and recalls.

- Flexible Costing: Each item can be costed uniquely — standard, average, FIFO, LIFO, or actual — giving you flexible cost control for both financial and operational decisions.

- Vendor Management: Manages vendor contracts, pricing tiers, and performance data in one place. You always know who delivers the best value and on-time performance.

- Cycle Counting & Accuracy: Make it easy to maintain accurate inventory through cycle counts or full physicals, eliminating write-offs or surprises.

- Seamless Transfers: Move inventory between warehouses or sites easily — with full intercompany accounting where needed.

In a manufacturing environment, poor inventory visibility means late jobs, wasted cash, and missed opportunities. With Infor’s Materials Management, planners and buyers can react immediately to changing demand — with the confidence that data is accurate and up to date.

Statistical Sales Forecasting converts guesswork into science. It uses your historical data — sales, production, and demand patterns — to automatically calculate accurate forecasts for every product, customer, and warehouse. Instead of relying on gut feel or spreadsheets, it gives you a data-driven picture of what’s coming, when, and how much you’ll need to meet it.

The system isn’t just about predicting sales — it helps you balance inventory levels, reduce carrying costs, and improve on-time delivery by aligning production and purchasing with true demand.

- “What-If” Analysis: Run scenarios to see how promotions, seasonality, or market changes can affect future demand — before making huge inventory or production decisions.

- Smart Forecasting: Automatically calculates forecasts using proven statistical models that adapt to your historical data. You can also combine them with input from sales teams or customers for a collaborative forecast.

- Dynamic Adjustments: Easily adjust forecasts for special situations — any new product launch or competitor activity — at the item or product-family level.

- Inventory Optimization: Calculates the perfect safety stock, reorder points, and order sizes for each item based on lead time, demand variability, and desired service level — so you never overstock or have stock outs.

- Top-Down Forecasting: For complex or highly configurable products, you can forecast components at a family level and let customer orders drive the final assembly — perfect for make-to-order, configure-to-order and engineer-to-order environments.

- Real-Time Alerts: Be notified when actual demand strays too far from forecast, to proactively adjust plans and avoid surprises.

With Infor Advanced Forecasting, you don’t just react— you stay ahead of it. Keeping inventory lean, production smooth, and cash flow strong.

Infor Document Management (IDM) is the paperless backbone of your operation — a centralized, secure system with in/out authority, where every business document lives, connects, and flows automatically with your ERP data. Instead of storing files in email folders, shared drives, or filing cabinets, IDM puts everything — invoices, drawings, HR forms, compliance documents, specs, contracts — in one place, tied directly to all transactions.

When you open a purchase order, you can see the signed contract, packing slip, and invoice right there — no hunting, no paper shuffling, no delays.

- Seamless ERP Integration: Never leave your ERP to find a document — IDM is built right in, linking files directly to records like POs, jobs, customers, and vendors.

- Centralized Document Repository: Every document — from shop floor specs to customer invoices — is stored in one secure database with version control and easy search tools.

- Digital Workflows: Replace manual routing with automated, rules-based workflows. Documents which move automatically for approvals, reviews, and archiving — no printing, emailing, or waiting for signatures.

- OCR & Barcode Scanning: IDM uses smart scanning to recognize documents, extract data, and file them instantly — perfect for accounts payable, production records, and HR paperwork.

- Electronic Signatures: Integrated DocuSign support lets you capture and store approvals digitally, cutting down delays and paper handling.

- Compliance & Audit Readiness: Every document and version is tracked with full audit trails — making compliance reporting or customer traceability fast and painless.

- Access Anywhere: Whether on the shop floor, in the office, or working remotely, your team can securely access documents from any device.

IDM eliminates the headaches and hidden costs of paper. It saves time on filing, searching, and auditing while reducing errors and improving collaboration across all departments. When someone needs any document — it is available and linked to the data that matters.

Infor Velocity Suite

Identify inefficiencies, automate workflows, and optimize business processes

Industries Use Infor CloudSuite Industrial

Metal Fabrication

Aerospace & Defense

Windows & Doors

Industrial Equipment

Plastic Fabrication

High Tech & Electronics

Medical Device

Prefab & Modular Home

Furniture Manufacturing

Rental Organizations & Field Service

Watch & Learn - Infor Functionalities

Find out if Infor fits with your operations

Frequently Asked Questions (FAQ) About Infor CSI

Infor CloudSuite Industrial is a cloud-native ERP solution designed for most manufacturing environments, offering comprehensive tools to manage operations, production, supply chain, project management, quality, service and customer relationships.

It's built for most any manufacturers, including those in industrial equipment, aerospace and defense, automotive, high-tech industries and even batch process.

Yes, it is a cloud-native ERP solution hosted on AWS, offering scalability, reliability, and security for industrial organizations.

It includes modules for finance, inventory, supply chain, CRM, human resources, project management, quality assurance/control, Field Service, advanced planning and scheduling and more.

Yes, it targets a diverse list of manufacturing environments including make-to-order, make-to-stock, engineer-to-order, and mixed-mode manufacturing.

Yes, Infor’s Factory Track shop floor execution tools that allow real-time tracking of jobs, labor, and materials updating job costs and job scheduling.

Yes, with Infor Mongoose Platform allows to configure, supporting user-defined fields, workflows, and personalized dashboards.

Yes, it provides smart device mobile access for most all features such as approvals, alerts, inventory tracking, and service management.

Yes, it supports multi-site and multi-company setups with centralized visibility and localized control. Multi-company consolidations and eliminations are built in.

It offers real-time inventory visibility, automated replenishment for forecasted and actual demand, with integration with demand planning and procurement.

Yes, it includes robust APS finite and infinite capabilities to optimize all resources and production sequences, resource allocation, lead times and ‘what if’ scenarios for proactive planning.

Yes, it includes Infor ION (middleware) and provides APIs and connectors for integrating with any type of third-party tools such as CAD, PLM, MES, and ecommerce platforms.

Security can be defined down to a field level. It leverages AWS security protocols and Infor’s built-in role-based access controls and audit trails to ensure data protection.

It includes embedded analytics, dashboards, and reporting powered by Infor BI, enabling data-driven decision-making.

Implementation is through Infor’s certified partners, using best practices and business process re-engineering for successful deployments. Essential Software Solutions (ESS) provides all ERP implementation, ongoing support, and maintenance services as Infor Gold Channel Partner.

Infor CSI provides integrated tools for managing engineering specs, engineering change control, BOM revisions, multi level BOMs and custom configurations, supporting full ETO workflows from design to delivery.

Yes, CSI supports traceability, audit trails, electronic records, and compliance tracking for ISO, ITAR, FDA, and most any regulatory compliance frameworks.

Yes, the platform includes quality control modules such as inspections, non-conformance tracking, corrective actions, and supplier quality.

CSI includes maintenance planning and asset tracking features to help reduce downtime, schedule preventative maintenance, and track work orders. Fully integrated with shop scheduling, preventative maintenance schedules remove the specific resources from capacity availability.

Yes, it includes features like Kanban support, visual scheduling, waste reduction tracking, and real-time shop floor monitoring to support lean initiatives.

Yes, it supports barcoding for most any data collection including, shop floor labor, and material transactions. It can also integrate with IoT devices and touch screens for real-time data capture.

CSI provides revision control, engineering change orders (ECOs), BOM part effectivity and part traceability throughout the product lifecycle. Infor Document Management and Document Lifecycle (forward and backward transaction genealogy) is included with Infor’s OS stack and can integrate with Infor PLM or other popular PLM tools.

Yes, through real time demand planning, APS, production scheduling, and order tracking, CSI helps manufacturers hit delivery deadlines without increasing overhead.

Yes, CSI includes supplier scorecards, purchase order management, and communication tools, improving vendor collaboration and procurement accuracy.

Infor CSI supports multi-division, multi-country, multi-language, multi-currency, multi-legislation environments, multi-warehouse and multi-manufacturing facilities, ideal for global manufacturing and supply chain management.

Yes, CSI includes subcontractor (vendor) order tracking, order dispatch, material issues, and vendor work-in-progress monitoring.

Yes, demand sales forecasting and sales & operation planning tools help manufacturers even with inconsistent demand, predict customer demand, improve planning accuracy, and reduce excess inventory.

It allows flexible production planning models, supporting MTO/ETO (high mix, short run), (low mix, long run) and even batch process workflows within the same ERP serving various manufacturing environments.

It is a native cloud deployed system powered by AWS. However, hybrid deployment and on-premises options are also available for specific cases.

Yes, it supports project costing, milestone billing, % complete revenue recognition, WBS (work breakdown structures with phases), integrated project financials and even native integration to MS Project for project-centric manufacturing.

Case Studies

Talk with an ERP advisor

Talk with an ERP advisor

Do you have questions about ERP selection, ERP implementation, ERP trainings or any other issues with digital transformation? Talk with one of our advisor, we'd be glad to help you.

Don't hesitate to contact. Our client policy is 'no string attached'.