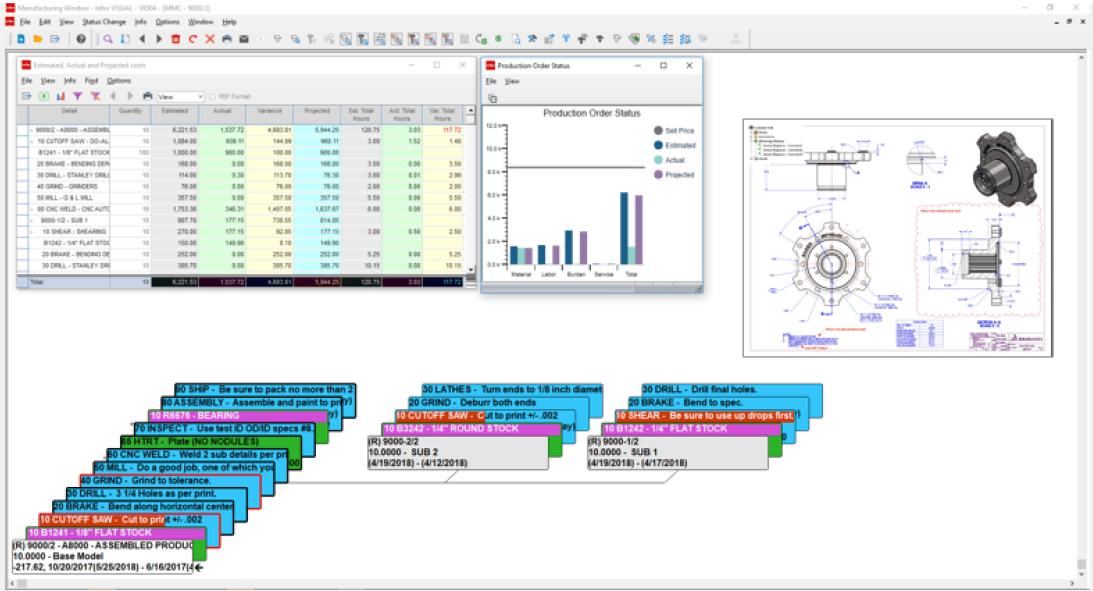

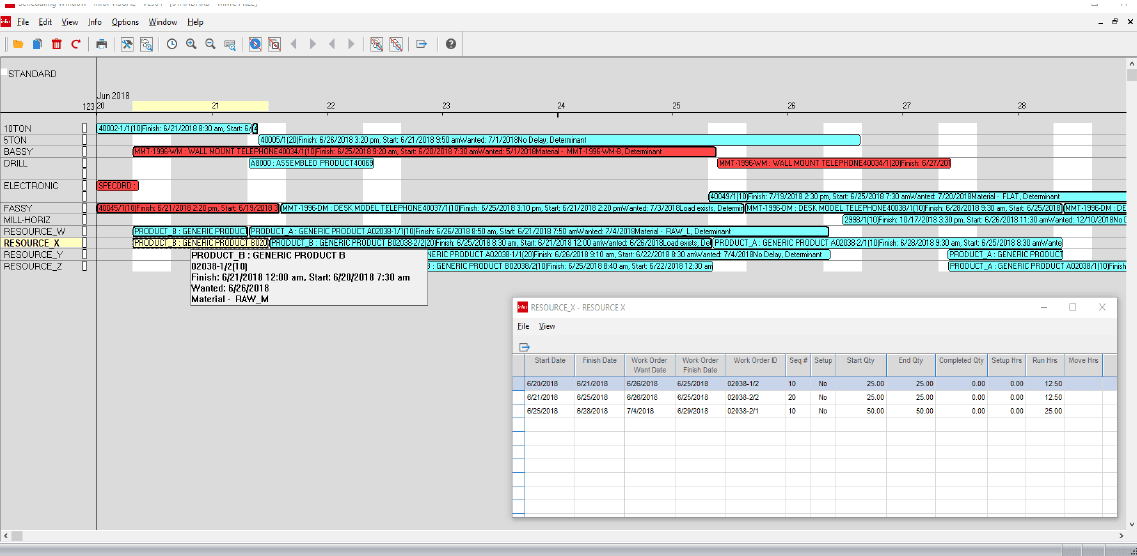

Every manufacturer will experience business challenges and opportunities. How quickly you can diagnose and respond to these challenges and opportunities can be the difference between liabilities and profits for your company. Infor VISUALs unique, graphical user interface provides “information at your fingertips”, in one screen, to proactively plan & schedule work orders on the shopfloor while being reactive (everything is only a couple of clicks away) to quickly respond to change.

Infor VISUAL is uniquely designed to support the goal of order-driven manufacturers: increasing throughput while minimizing or maintaining overhead, ultimately driving profits.

Order-driven manufacturing is highly complex, and guessing what the next step should be is never the best option. Manufacturers need to proactively visualize the impact of any material shortage, capacity constraint, and/or bottleneck as well as factors that impact accurate quoting, calculated delivery dates, shorter lead times, quality assurance, supplier coordination while leveraging the delicate balance of customer service.

To achieve the GOAL, Advanced Planning & Scheduling (APS) had to be architected into Infor VISUAL (never a bolt-on), and was awarded a patent (#5,000,500) for its unique ability to schedule Concurrent Resources – essential for complex manufacturers. While every ERP can show a Gantt chart and appear to handle the challenges of APS, VISUAL continues to be the only ERP in the market to have customers successfully using its native APS capabilities.