Infor is designed for Equipment Manufacturers

3,000+

25+

300+

Infor benefits include…

Infor benefits include…

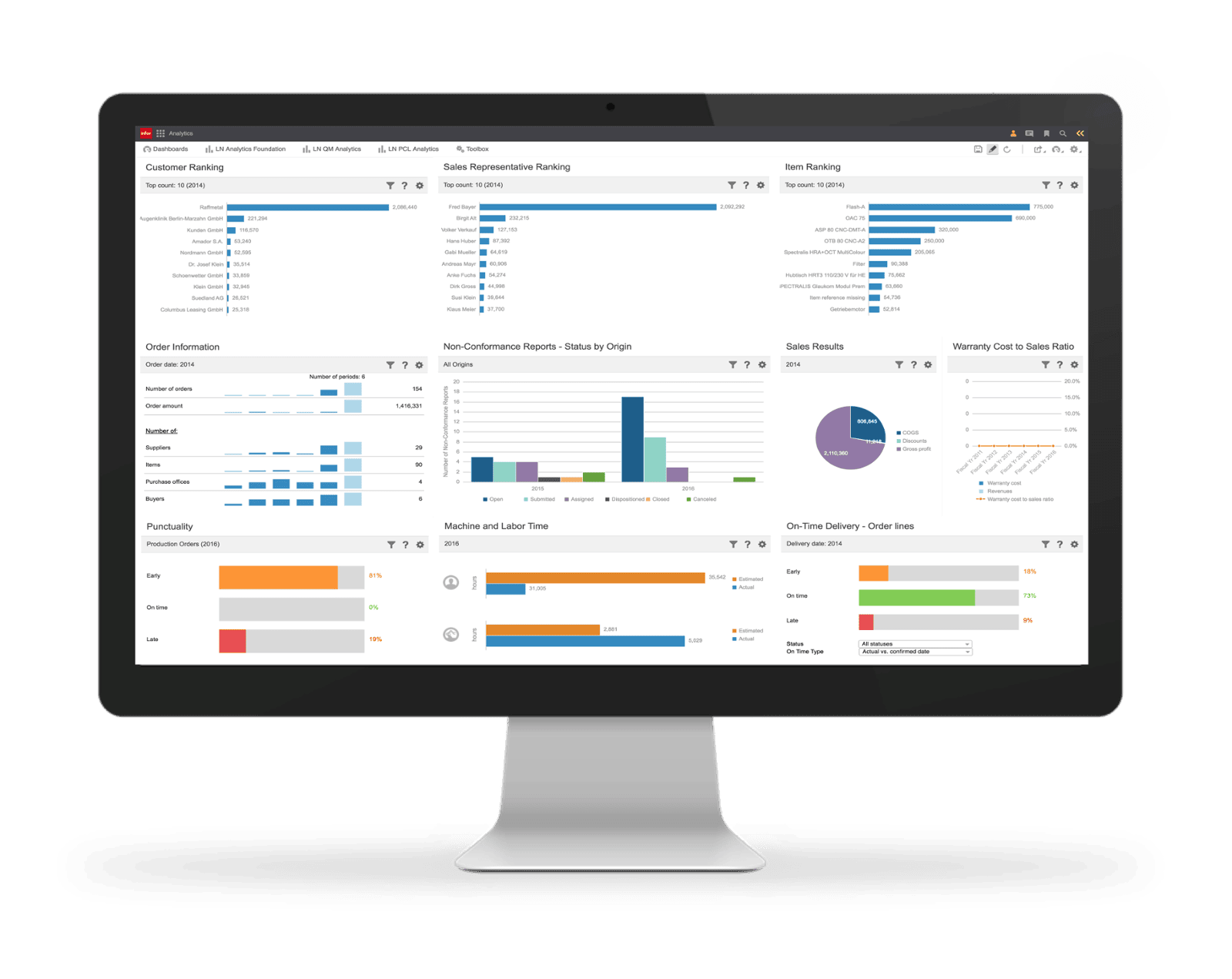

Meeting the needs of complex equipment manufacturers (high mix/low volume and low mix/high volume) all in one integrated system

- Continuous visibility across your entire facility

Manage and balance internal capacity versus what should be sub-contracted. Tightly managing your supply chain throughout internal or external resources

- Featuring end-to-end functionality

- Accessible wherever you need it

- Intuitive and user-friendly

- Cost-effective ownership

Infor Industrial Machinery & Equipment Portfolio

Read a Case Study

Talk with an ERP advisor

Do you have questions about ERP selection, ERP implementation, ERP trainings or any other issues with digital transformation? Talk with one of our advisor, we'd be glad to help you.

Don't hesitate to contact. Our client policy is 'no string attached'.