Companies operating across multiple facilities often struggle with inefficiencies such as inventory duplication, redundant processes, and poor coordination across plants. They need an integrated, cloud-based ERP solution to manage multi-site operations while standardize processes and achieve end-to-end visibility.

We will review Infor CloudSuite Industrial (CSI) in this blog post. This solution paper outlines how Infor CSI can solve key challenges associated with multi-site manufacturing, automating sales orders and shipping processes.

Business Challenge

For discrete manufacturers operating in multiple locations, managing operations across plants often introduces significant inefficiencies and risks. The absence of a unified ERP environment typically leads to:

- Disconnected Systems and Data Silos: Each facility may use different systems or standalone tools for production, inventory, and procurement.

This fragmentation results in a lack of real-time visibility and makes data consolidation labor-intensive and error-prone.

- Redundant and Inconsistent Processes: Without a standardized approach to production planning, procurement, and order fulfillment, each site develops its own workflows. This redundancy leads to duplicated efforts, inconsistent quality, and reduced economies of scale.

- Difficulty Coordinating Demand, Supply, and Capacity: Without integrated planning across locations, companies struggle to balance supply and demand. Overproduction at one site and underutilization at another are common, along with missed opportunities for inter-facility collaboration and load balancing.

These challenges limit a company’s ability to scale efficiently, respond to demand fluctuations, and maintain a lean supply chain—ultimately impacting profitability and customer satisfaction.

Case Example: Multi-Plant Discrete Manufacturer in North America

A mid-sized manufacturer of industrial components operated four production plants across the U.S. and Canada. Each facility ran its own instance of legacy ERP systems, resulting in limited visibility between locations and no centralized inventory control.

Key Issues Faced

- Inventory Duplication: The same raw materials were overstocked at multiple plants due to lack of visibility into shared stock levels.

- Inefficient Scheduling: Production planning was handled independently at each site, leading to missed opportunities to redistribute workloads and avoid bottlenecks.

- Disjointed Order Fulfillment: Orders from large OEM customers were split across plants without a unified view of capacity, resulting in delays and frequent expediting costs.

- IT Overhead: Maintaining and customizing four different ERP systems consumed considerable IT resources and budget.

The company recognized that without an integrated, multi-site ERP platform, it could not effectively scale or compete with more agile rivals. Infor CloudSuite Industrial was selected to unify operations across all sites and implement coordinated planning and fulfillment strategies.

Infor CSI Solution

Infor CloudSuite Industrial (CSI) is purpose-built to support multi-site discrete manufacturing, offering the tools and architecture needed to unify operations while allowing each plant the flexibility to manage its own processes.

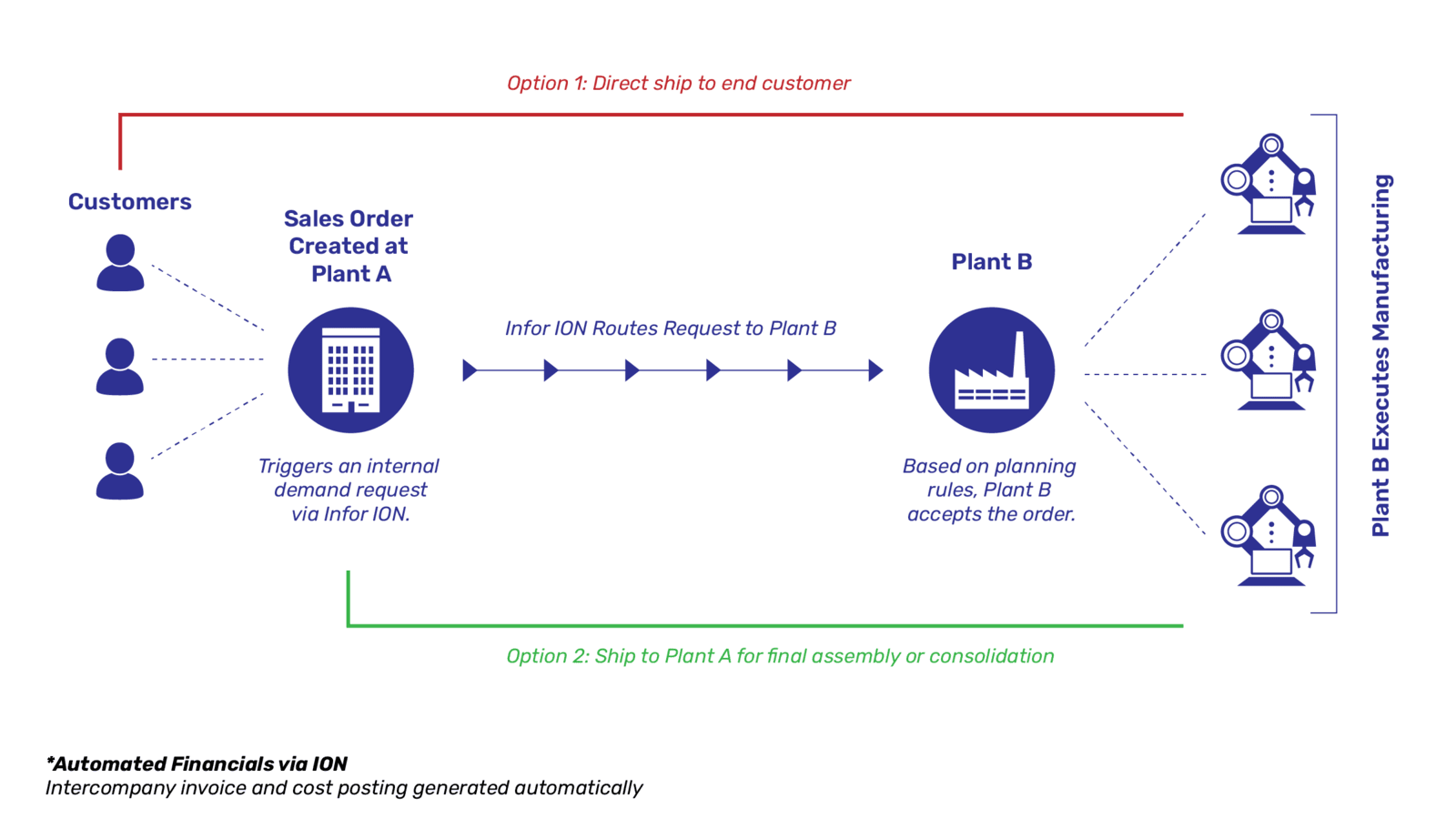

Multi-Site Configuration and Intercompany Workflows

Infor CSI enables manufacturers to manage multiple facilities within a single tenant or across logical entities, with built-in capabilities for:

- Intercompany transfers and transactions

- Centralized or distributed procurement

- Automated material movements and order fulfillment between sites

Shared Master Data for Consistency

Standardizing data across locations is critical for operational alignment. Infor CSI provides:

- Centralized management of items, bills of materials (BOMs), routings, and vendors

- Global revision control and engineering change management

- Unified pricing and customer data

Flexible Planning Models

Infor CSI supports both centralized and decentralized planning, empowering organizations to:

- Aggregate demand across sites for optimized MRP/APS runs

- Share production capacity and balance workloads across plants

- Use forecasting and inventory buffers to drive smarter replenishment decisions

Together, these capabilities allow manufacturers to reduce waste, increase agility, and respond quickly to shifting customer or market demands—all while operating as a cohesive organization across multiple locations.

Infor CloudSuite Industrial provides a robust, flexible architecture that simplifies the coordination of multi-site operations, both at the system level and within day-to-day processes.

This process was running by 4 different ERP platforms. It caused a lot of disruptions and inefficiencies, with Infor CSI, 4 different locations (headquarter, manufacturing plants, and warehouses) connected to each other and Infor ION automatize the processes and shipment to the customers or final assembly.

By implementing Infor CloudSuite Industrial to streamline its multi-site operations, the manufacturer in our scenario achieved tangible improvements in efficiency, visibility, and scalability. Below are key benefits that companies can expect:

20% Reduction in Excess Inventory: With centralized inventory visibility and inter-site transfers, the company significantly reduced overstocking by redistributing materials across plants instead of reordering unnecessarily.

Standardized Processes Across Sites: Unified BOMs, routings, and quality procedures eliminated local variations and enabled consistent production outputs, regardless of facility. This also simplified training and compliance.

Improved Production Agility: Through shared planning and capacity coordination, the company gained the flexibility to shift work orders and balance load between facilities—cutting lead times and avoiding late shipments.

Lower IT Overhead: Migrating to a single, cloud-based ERP eliminated the need to maintain and integrate multiple legacy systems, reducing IT support costs and freeing resources for innovation.

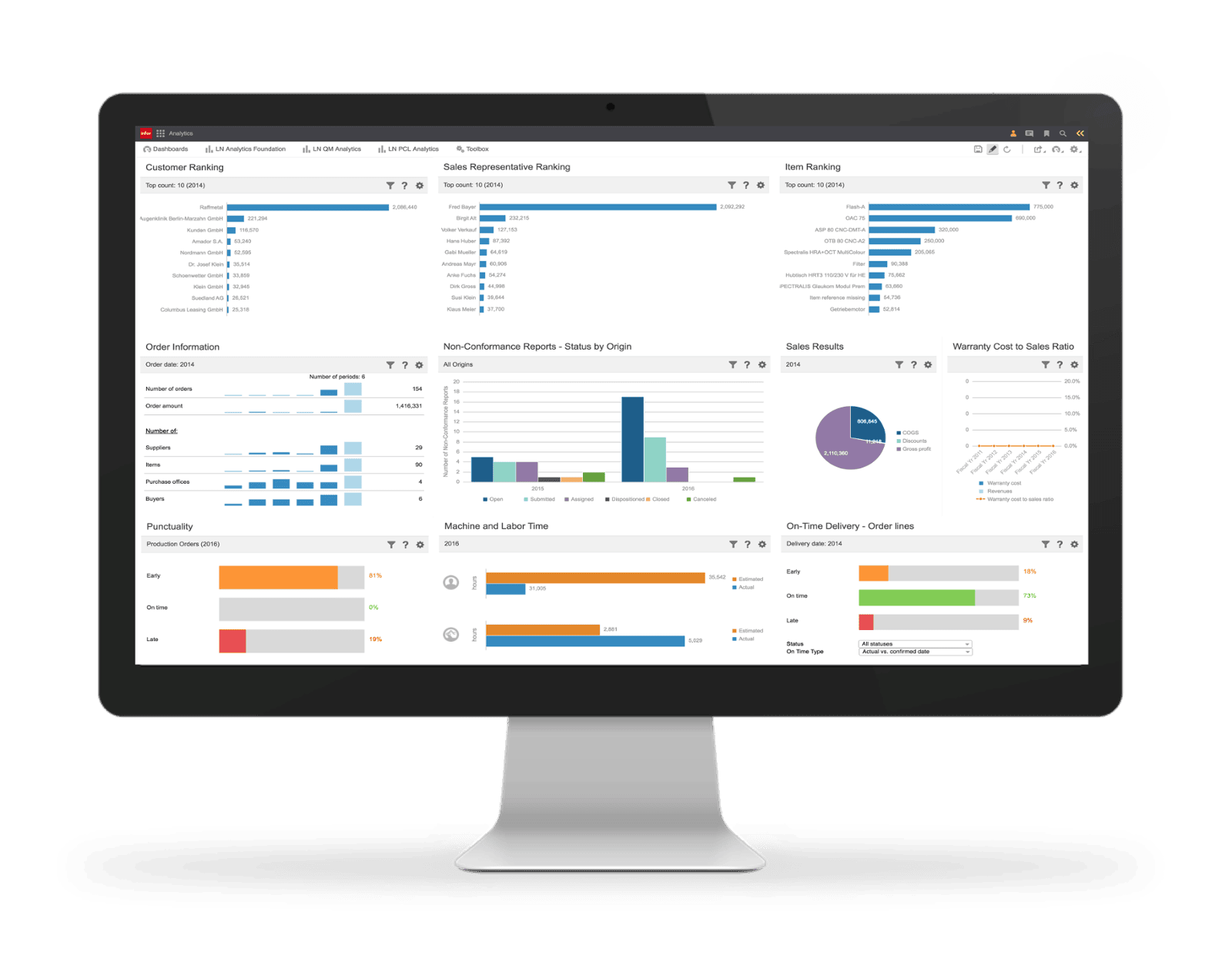

Effective Decision-Making: Real-time dashboards and analytics provided cross-plant KPIs, empowering leadership to make fast, informed decisions on procurement, planning, and logistics.

These results not only improved day-to-day operational performance but also positioned the organization to scale with confidence and compete globally.

Infor CloudSuite Industrial

Infor CloudSuite (Syteline) is a powerful Cloud ERP solution designed specifically for SMB manufacturers, project management teams, and field service organizations. Many customers replace multiple separate data silos with this integrated, end-to-end ERP system that streamlines operations and manages all aspects of their business.