Real-time operational visibility is an essential competitive advantage. The ability to monitor and respond to production events affects downtime, throughput, and decision-making agility.

What is real-time visibility in manufacturing?

Why real-time visibility matters?

- Detect and resolve issues now!

- Real time key performance indicators (KPIs)

- Accurate production planning and increased throughput

- Make informed, data-driven decisions

Visibility is only possible with three components: an integrated ERP system, real-time shop floor data capture, and visual dashboards with workflow automation.

Infor Cloudsuite is your unified system of record for all operations. An integrated Infor solution ensures consistency and eliminates duplication. Instead of overnight batch processing, real time updates providing every department access to current, accurate information.

Capturing Data

Infor captures data from the shop floor, providing an integrated manufacturing execution system (MES) including:

- Electronic inventory and job tracking

- Time and attendance logging

- Labor and machine utilization monitoring

- Materials movement and consumption recording

Data captured is written directly to the Infor database. Everything is built in, never 3rd party software bolted on. Everyone can monitor order status, material usage, and labor performance.

Capturing Data

Even more, Infor OS (Operating Service), is Infor’s technology stack used by industry giants such as Disney. Providing;

- Role-based dashboards, KPI tracking and Automated alerts

- Workflow and exception routing

- Integration with IoT devices, MES, and external platforms

- AI (artificial intelligence) used by many customers already

Here's a simplified workflow showing how real-time visibility is achieved through Infor CSI and its supporting tools:

| Process Stage | Technology | Results |

| Job started on shop floor | Factory Track | Operator scans barcode; labor time begins tracking |

| Material issued | Factory Track | Inventory is deducted immediately |

| Job completed | Factory Track -> CSI | Status updated, finished goods recorded |

| Dashboard updated | CSI -> Infor OS | KPIs reflect job completion, scrap, labor hours |

| Alert triggered | Infor OS | Manager notified of any performance deviations |

Components Needed to Build Stack

To implement a full real-time visibility system, manufacturers will need the following components:

| Component | Purpose |

| Infor CSI (Cloud ERP) | Centralized system of record |

| Factory Track | Real-time data collection from the shop floor |

| Infor OS | Dashboards, alerts, workflows, and integrations |

| Barcode / Mobile Devices | Operator inputs and scanning hardware |

| Implementation Partner | Setup, configuration, and deployment supports |

Infor CSI helps manufacturers move beyond static reports and delayed visibility. With integrated planning, real-time data capture, and actionable analytics, manufacturers can monitor operations as they happen — and act with confidence.

By building a visibility stack with Infor CloudSuite, organizations position themselves for improved responsiveness, better planning accuracy, and scalable operational control.

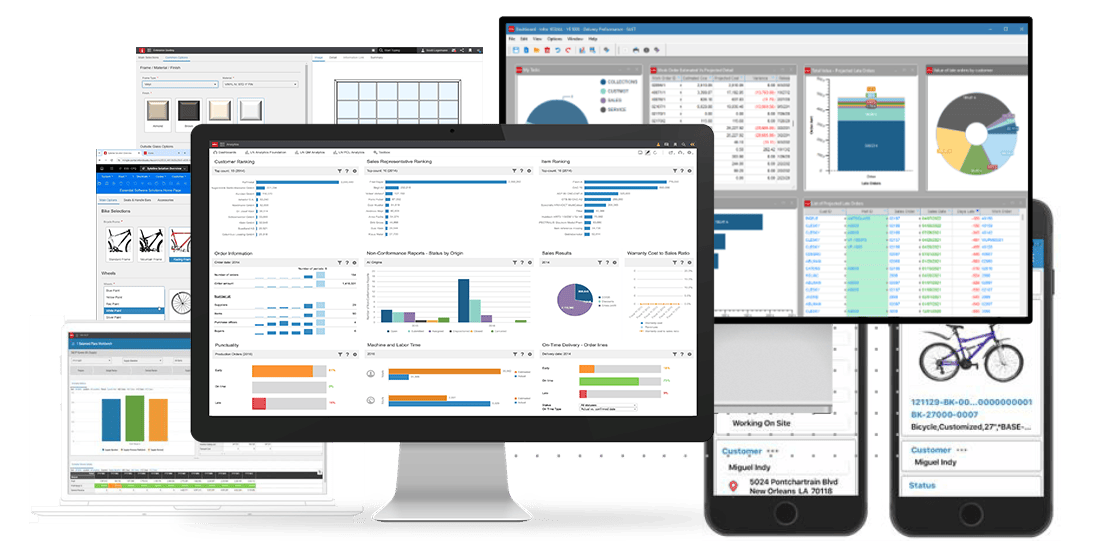

Explore Infor CloudSuite

Infor CloudSuite (Syteline) is a powerful Cloud ERP solution designed specifically for SMB manufacturers, project management teams, and field service organizations. Many customers replace multiple separate data silos with this integrated, end-to-end ERP system that streamlines operations and manages all aspects of their business.