Unplanned downtime, inefficient use of resource, and delays in responding to machine failures are common challenges for manufacturers. A powerful solution to these headaches is IoT.

While ERP provides business-wide transactional and operational visibility, IoT connectivity ensures real-time visibility of granular data on key performance indicators, which allows you to make immediate and informed decisions.

What is the real value of IoT-ERP Connectivity?

- Process Monitoring

- Interactivity with Physical Environments

- Depth of Real-Time Data

- Predictive Maintenance for Assets

- Energy Efficiency

Manufacturing Process Monitoring

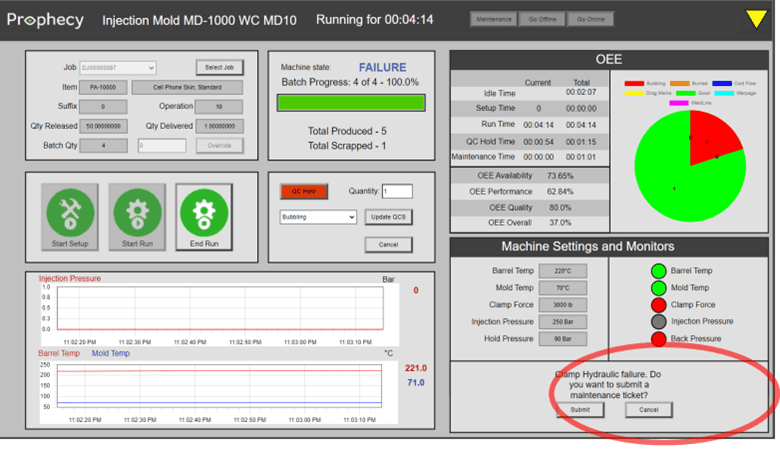

To ensure production continues to flow without surprises, monitoring machines in real time minimizes breakdowns without human intervention. Advanced process monitoring software, such as Prophecy IoT, employs algorithms to track parameter ranges, including temperature, pressure, and production speed, across different areas within a facility and even across multiple geographical locations.

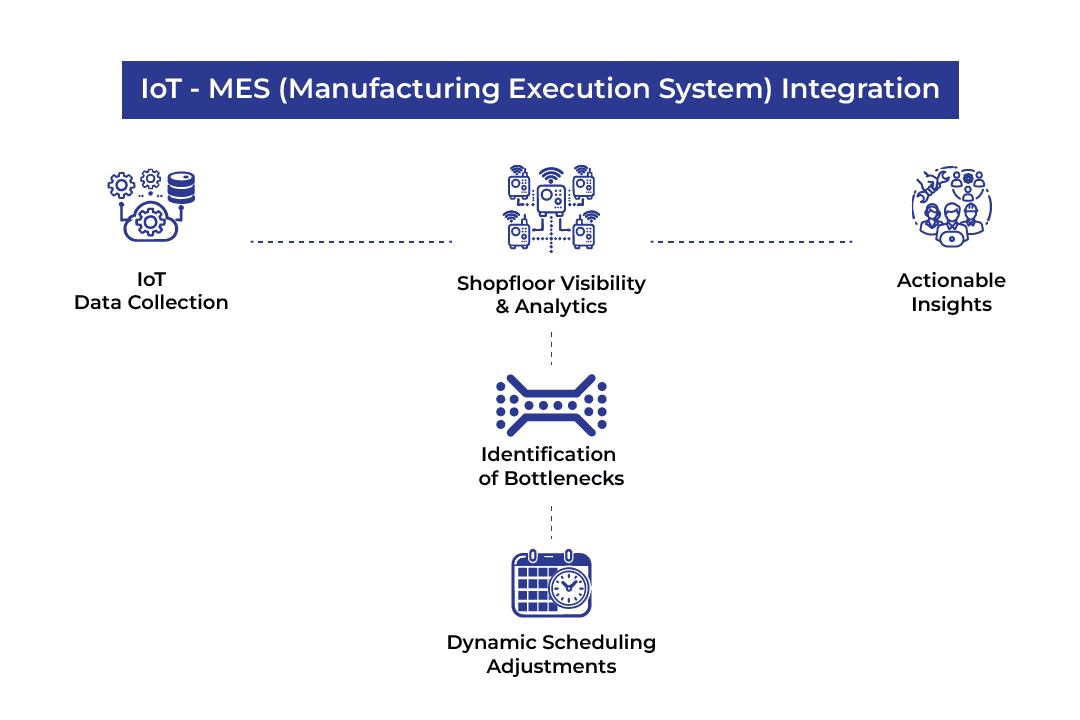

Identifying and Solving Bottlenecks in Manufacturing

- Predict slowdowns in specific machines or workstations.

- Signal when materials are delayed reaching a workstation on time.

- Monitor worker productivity and resource utilization.

- Provide predictive insights to prevent future bottlenecks.

Interactivity with Physical Environment

Quality Control

Predictive Asset Maintenance

Conclusion

Curious about how Prophecy IoT and Infor CloudSuite ERP integration can revolutionize your shop floor?

Join our webinar with Godlan on October 16, 2024, where we'll explore IoT-ERP connectivity and the advantages it brings to your operations.