An ERP Selection Process That Guarantees Results

Written by Andy Pratico

Budget Approval Dance

The middle manager can get so obsessed with budget approval; and the upper manager can get so consumed in confirming the selection process is sound, that the most important objective in selecting a new system is often overlooked. The most important goal should be to ensure your company is successful with the new system! All other consideration should be secondary.

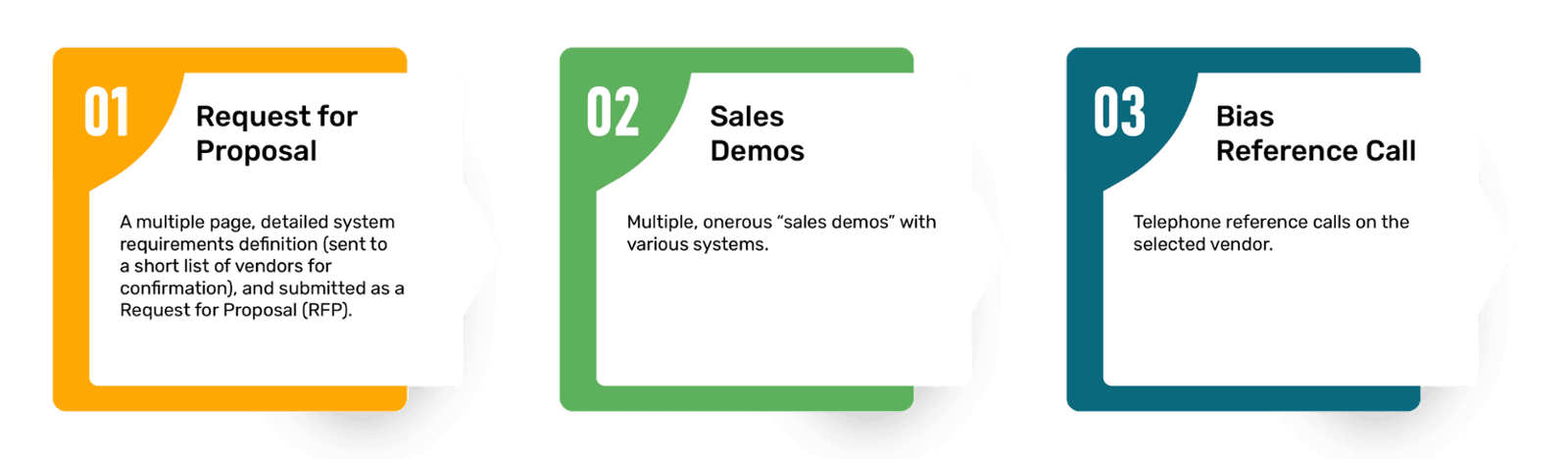

Legacy Selection Approach

Legacy Approach

Step 1

Step 2

Step 3

Step 4

Common Sense Approach

Step 1

Step 2

Step 3

Step 4

How to Get Value with Sales Demo?

Consider it can take years to become fluent with any new ERP. Yet ERP sales demos usually last only a few hours. What can you possibly comprehend from watching a 3 hr sales demo?

If you fail to implement

why do you care what software does?

For more than 40 years, Andy Pratico has worked with hundreds of manufacturers. During this time he has seen many implementation success stories, but sadly even more failures. To help companies increase their probability of success, Andy presents common sense workshops.

Reference: This article was written by Andy Pratico for the first time for National Tool & Machine Association (NTMA).

Offer You Can't Refuse

Today I had the privilege of learning from Andy about ERP options. He presented many possibilities at a high level (first meeting). His breadth of knowledge and experience were very beneficial and I would recommend you consider him when you are exploring ERP options.

Carl Markwart

BAUCO Access Panel Solutions Inc.

Finance Manager

Fair View of the ERP Evaluation Process

Andy shared a Webinar on LinkedIn that I found to be well informed and based on accurate knowledge of the ERP industry. Not only was the Webinar entertaining, but it was also a very fair view of the ERP Evaluation process. Definitely worth a watch!

Michelle Harvey

Chief Executive Officer

Combined Management Consultants

Knowledge of ERP and Honesty

Although we did not end up working together, I was impressed by Andy's breath of knowledge of our ERP system and his honesty. He was candid on what he can provide and where he can add value and we both agreed that Cascade Aqua-Tech's current need is not a good fit for Andy. I would recommend anyone looking to upgrade or replace their ERP system to seek Andy out for an open and honest discussion on what will work best for them and where he can add value.

Simon Tran

CFO/Director of Operations

Cascade Aqua-Tech Ltd.